Complete Guide to Different Types of Gloves

Occupational Health & Safety reports that hand injuries account for around 40 to 60% of injuries suffered on the job, costing around $7,500 a claim, so it is evident hand protection is not something companies can afford to overlook. In many cases, hand protection means safety gloves. This gear is the first line of defense between your hands and dangerous items or materials you might encounter during the workday.

However, not all protective gloves are created equal, and knowing how to choose the right gloves for the right job is the first — and potentially most important — step you can take to avoid hand injuries. In this guide, you will learn about various types of personal protective equipment (PPE) for the hands. As a result, you and your team of healthcare workers can ensure utmost safety while on the job.

Common Gloves for Safety and Hygiene Uses

1. Latex Gloves

The primary function of latex gloves is to protect hands against bloodborne pathogens, biohazards and chemicals. They are very tactile, so some professionals in high-precision careers, such as surgeons, swear by latex. These gloves are produced from rubber tree sap and have been a staple in the medical field and other industries for decades.

Best Uses for Latex Gloves

When you need to handle biological materials or water-based solutions, latex gloves are an excellent choice. That is because latex gloves are both sturdy and comfortable. As a result, they are used in many settings — dental, childcare and eldercare, food service, beauty and even in some automotive and manufacturing situations.

Limitations of Latex Gloves

It is important to note that latex gloves do not offer adequate protection around sharp objects, so they do not prevent puncture wounds. They are also not the best choice for handling organic solvents. It can escape the wearer’s notice when a latex glove sustains a small puncture or tear, so extra care must be taken around sharp objects. Also, some individuals have severe allergies to latex and will need to be provided with an alternative, like nitrile.

2. Nitrile Gloves

Unlike latex, which is made from natural rubber, nitrile (nitrile butadiene rubber), is produced from synthetic rubber. It is stronger and more puncture-resistant than latex, and often, it is more economical. Additionally, using nitrile reduces the risk of an allergic reaction.

Best Uses for Nitrile Gloves

Because nitrile gloves protect against biohazards, grease, oils and chemicals, many professionals in scientific and healthcare settings wear them. Additionally, they are popular with tattoo artists and auto mechanics. All in all, nitrile gloves are a top PPE option for a general-purpose disposable glove.

Limitations of Nitrile Gloves

Some people do not like the tactile sensation produced by nitrile gloves and feel their dexterity and freedom of movement is impeded in a way that it is not with latex gloves. While this preference is an important consideration when working with fine instruments or small parts, manufacturing is becoming increasingly sophisticated, and many users can barely tell the difference between nitrile and latex today.

3. Vinyl Gloves

These gloves are made from polyvinyl chloride (PVC) with a plasticizing agent added for flexibility. The main advantage of vinyl gloves are their low cost, making them a popular choice for situations where gloves are changed frequently and discarded.

Best Uses for Vinyl Gloves

For situations that do not involve hazardous chemicals or pathogens, such as food service, housekeeping and certain medical procedures, vinyl gloves are a cost-effective option. These gloves are also a good choice for those who want to avoid contact with allergens. If you need a simple, light-duty glove, vinyl is a top pick for many professionals.

Limitations of Vinyl Gloves

While vinyl gloves are softer and have a texture and feel that some people prefer, they are less durable than nitrile gloves. Therefore, vinyl gloves should not be used when handling infectious materials. They also offer less breathability than nitrile and latex and can cause a wearer’s hands to perspire after extended use.

Other Types of Medical and Safety Gloves

Aside from latex, nitrile and vinyl, you have many other glove options for the tasks you need to perform. It often helps to have a variety of glove options readily available. This way, you can ensure you and your employees have the correct PPE for the job at hand. Here are several other gloves to consider.

1. Polyethylene Gloves

Polyethylene is a polymer and one of the most common plastics used today. Manufacturers use it to make plastic bags, bottles, films and a number of other products, including clear plastic gloves. These gloves offer a good value for a low price, so they are often the best types of disposable gloves.

This type of PPE is loose-fitting for quick and easy glove changes and help to maintain a hygienic environment in low-risk situations like food service and preparation. They function to keep germs away from people and food but do not offer a layer of protection from substances like food-grade oil.

2. Neoprene Gloves

Neoprene, sometimes called neoprene rubber, was the first synthetic rubber. It is a polymer used to make wetsuits, hoses, gaskets, weather stripping and many other products. These gloves are tough, versatile and often impervious to liquid, so they are an excellent choice for situations where skin and hands must be in prolonged contact with substances like alcohol, peroxide, fuel, hydraulic fluid, acids, bases, hydrocarbons and organic acids.

3. Butyl Rubber Gloves

Butyl rubber is a synthetic rubber. Its characteristics are strength, flexibility and a long shelf life, but the most unique aspect of butyl is that it is one of few materials — and the only known elastomer — impervious to gasses. Butyl rubber is resistant to acids and alkalines, ozone, hydraulic fluid and ketones. It remains functional in extreme temperatures from -50 to 250 degrees Fahrenheit. These gloves can even stand up to rocket fuel and highly corrosive acids like nitric, sulfuric and hydrofluoric.

Butyl rubber gloves are used when working around any of the hazardous chemicals mentioned above. They are sturdy, strong and offer superior protection against dangerous substances at the expense of being thick, bulky, limited in touch sensitivity and unsuited to precision work.

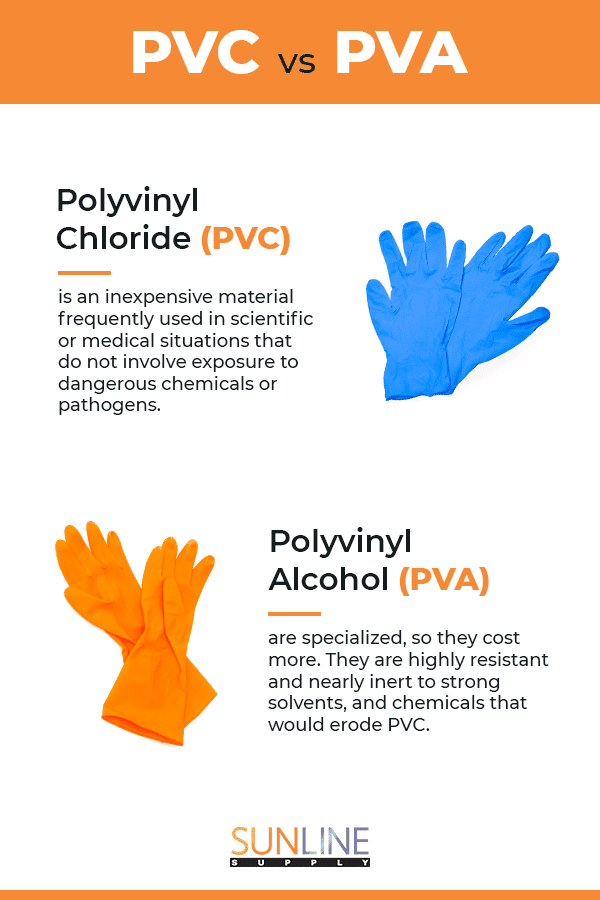

4. Polyvinyl Chloride (PVC) or Polyvinyl Alcohol (PVA) Gloves

Though these gloves have similar names, they have vastly different compositions, applications and prices.

Polyvinyl chloride (PVC) is an inexpensive material frequently used in scientific or medical situations that do not involve exposure to dangerous chemicals or pathogens, though PVC gloves can resist alcohols, salts and water solutions. Many low-priced, disposable vinyl gloves are constructed from PVC.

On the other hand, polyvinyl alcohol (PVA) gloves are specialized, so they cost more. They are highly resistant and nearly inert to strong solvents, and chemicals that would erode PVC, natural rubber or neoprene gloves. PVA is resistant to cuts and punctures, but it is highly susceptible to water and light alcohol. PVA gloves are used in scientific, industrial or laboratory situations that call for the handling of strong solvents.

5. Thermoplastic Elastomer (TPE) Gloves

Thermoplastic elastomer is a polymer that can be shaped when heated, and it has about the same flexibility and feel as natural rubber. These polymers are considered specialty resins and are manufactured at lower quantities and higher price points. TPE gloves are used in many of the same ways as vinyl, PVC and polyethylene gloves — food service and preperation, light cleaning and other low-risk tasks.

The advantage of TPE gloves is they are better for the environment, as the polymers can be recycled and reshaped. Overall, they are resilient and can replace single-use gloves in a number of circumstances for companies concerned with sustainability.

6. Cloth Gloves

PPE made from fabrics like wool and cotton protects hands from rough surfaces and minor abrasions and can safeguard against minor temperature changes such as those in refrigerated warehouses. However, cloth gloves cannot prevent cuts or puncture wounds and most do little to keep chemicals or other liquids away from hands.

Most often, cotton gloves are used when handling materials that could become damaged from the oils on human skin. They are also sometimes called liners and are worn beneath other gloves. Coated cloth gloves add another layer of protection by applying a coating to the outside of the gloves to boost thickness, strength and chemical resistance. Coatings can reduce the effects of alkalinity from materials like brick, so these gloves are used frequently in construction.

7. Leather Gloves

A quality pair of leather gloves can last many years with proper care. Leather, depending on its thickness, can be highly resistant to cuts, abrasions and punctures. It is comfortable, conforms to the shape of the hand and allows for freedom of movement. It also offers protection from the elements and even a slight degree of chemical resistance.

However, without proper attention, leather can become dry and cracked, at which time its protective properties will be diminished. Leather gloves are also susceptible to heat damage, so if they are intended to prevent burns, it is best to include a liner, which is a technique often used by welders.

8. Norfoil Gloves

Norfoil gloves are effective against extended contact with even the most hazardous chemicals. They are silver in color, resemble aluminum foil and are constructed from up to five layers of compacted fabric. The gloves are laminated with both high-and low-energy polymers that allow them to resist many chemicals for several hours.

Norfoil gloves can be worn as a liner for an added layer of protection. Their major disadvantage is the degree to which they can impede movement and dexterity.

9. Viton Gloves

“Viton” is the trademarked name of a fluoropolymer elastomer and synthetic rubber compound created by DuPont. It is the most chemically resistant rubber available on the market today and can protect against:

- Polychlorinated biphenyls (PCBs)

- Benzene

- Chlorinated solvents

- Aniline

- Aromatic and aliphatic hydrocarbons

10. Aluminized Gloves

Aluminized gloves are designed for working in the extreme heat common in foundries, laboratories, kilns and other industrial situations. By reflecting ambient and radiant heat, they can protect your hands from temperatures up to 2,000 degrees Fahrenheit.

11. Cut-Resistant Gloves

Like injuries that result from coming into contact with dangerous chemicals, incidents like cuts, abrasions and punctures can be prevented with the proper equipment. Cut-resistant gloves are ranked according to strength, hardness, lubricity and rolling action. Gloves that meet all four of these criteria will be rated higher than those that meet only one or two.

However, lower-rated gloves do not always imply lower quality, and they might be perfectly suitable in many situations. Manufacturers follow the guidelines put in place by the American National Standards Institute (ANSI) when determining gloves’ cut-resistance rating. Much of the rating is based on the materials used in the gloves’ construction, such as:

- Kevlar: Kevlar is a synthetic fiber, and it offers high cut resistance in addition to being five times stronger than steel per unit weight. Kevlar is also fairly lightweight, comfortable and flexible. Its heat- and flame-resistant properties make it an excellent option for restaurant and kitchen protection and a wide array of other applications. Kevlar has an ANSI rating of A2.

- Spectra: Spectra is another synthetic fiber made from polyethylene. It has the unique characteristic of offering cut resistance even when wet. Spectra is up to 40% stronger than aramid fibers like Kevlar and 15 times stronger than steel per unit weight. It is extremely lightweight, flexible and comfortable and also offers ultraviolet (UV) and chemical resistance. Spectra fiber gloves are rated between A4 and A5.

- Dyneema: Another synthetic, Dyneema is spun from polyethylene and is extremely durable — 15 times stronger than steel and 40% stronger than aramids, like Spectra. It offers UV resistance and superior protection against heat and cold. Dyneema is rated A5 by the ANSI.

- Metal mesh: Metal mesh, which is created with interlocking metal rings or links, offers one of the highest levels of cut-resistance available and is used in industries where sharp and heavy tools must be handled frequently. They are generally constructed of corrosion-resistant stainless steel and are therefore easy to keep clean with soap and water. Metal mesh gloves are surprisingly lightweight and offer a good range of motion, as well.

Considerations for Choosing the Best Types of Gloves

As you can see, the gloves available to protect employees range from thin plastic that prevents contact with food all the way to specialized gloves to resist highly dangerous chemicals. Depending on your industry and your staff’s daily tasks, you likely already know what types of gloves will work best. However, you may want to consider a few more points before deciding which gloves are the correct ones for your needs.

- Industry requirements: If you are operating in the medical or dental fields, you will be required by law to use gloves that meet certain requirements. Medical gloves, for example, are regulated by the Federal Drug Administration (FDA) and considered Class I medical devices. Though they can look and feel very similar, there is a difference between general use gloves for food service and those used for healthcare practices. For food service, health codes can dictate when gloves must be worn and some of their features.

- Length: From the fingertip to the glove opening, gloves can end at the wrist or extend beyond the elbow. Longer gloves are essential in situations where workers must submerge their hands and arms or when they cannot risk exposing the skin of the arm.

- Elongation: Elongation refers to how far a glove can stretch before it tears. Medical gloves are required to have an elongation of at least 300%.

- Thickness: Clearly, the thicker the glove, the more protection it offers, so more hazardous practices require thicker gloves. That said, you should be aware that thickness can sometimes impede flexibility and movement. If dexterity is a must for your applications, you may want to avoid thicker gloves.

- Fit: A proper fit is essential to getting maximum protection from your gloves. If gloves are too small or large, they can make working uncomfortable and difficult.

- Shelf life: The protective properties of some gloves begin to break down over time, which can be a major problem when you or your employees depend on them to avoid injury. It is crucial to choose gloves with a shelf life that will allow them to be used while they are most effective. At the same time, it is important to keep gloves stored in a cool, dark place so they reach their maximum shelf life.

- Chemical resistance: There are two types of chemical exposure you might encounter on the job. Incidental contact occurs when a substance splashes the glove. When working with mild chemicals in situations where incidental contact is possible, disposable gloves with some chemical resistance are often sufficient. However, if employees will be in extended contact with chemicals, they will require reusable gloves specifically designed for the types of chemicals they will be handling.

- Puncture and cut resistance: The ASNI rating you will choose for cut-resistant gloves will depend entirely on how the gloves will be used. Clearly, if you require gloves with superior cut resistance, you should prioritize gloves made from a material like Spectra so your employees can remain protected while working.

- Price: While safety is of the utmost importance, every business has a bottom line. Fortunately, it is entirely possible to find gloves that will meet all of your needs and still fall within your equipment budget.

- Comfort and preference: Compliance and protection are crucial, but gloves should be comfortable and not impede work. Besides, employees are more likely to comply with safety requirements when their equipment suits them. As a result, you may want to stock several types of gloves — depending on your industry’s practices — to ensure employees have the PPE they need for their daily duties.

Shop Disposable Gloves From Sunline Supply

Sunline Supply offers a wide range of disposable gloves to meet your needs. We encourage you to contact us if you are unsure of the best gloves for your situation, as we will be happy to help you select the perfect option. We have many decades of experience in distributing protective equipment and are confident that we can provide you the best products and best service.

We work with trusted manufacturers around the world to bring you the highest quality, expertly selected, certified gloves. Learn more about Sunline Supply or shop our PPE today.

Thank you for such a thorough explanations of the many different types of gloves.